Could any1 provide guidelines advice on designing RC Footing Foundation supporting a RC Beam every 6m. This paper aimed to optimize the gantry crane scheduling in the container sea-rail intermodal transport yard.

Adjustable Soleplates Gantry Rail

A-frame gantry crane 2 ton is a common crane with A shape structural design stable to move and operate meeting special requirements of most crane customers.

. Various control options The gantry crane can be delivered with pendant control or wireless remote control and it has higher performance since its smart optional systems. As experts in our field Gantrail have the experience resource and insight to deliver. Ensuring that a system is installed with the very highest levels of planning analysis and safety is critical to overall programme efficiency.

Rubber tyred type rail mounted type. If you plan on lifting 500 pounds or more youll want to find a steel DIY gantry crane design. Foundation for gantry crane rail.

ASME 830 STANDARDS COMMITTEE Safety Standard for Cableways Cranes Derricks Hoists Hooks Jacks and Slings The following is the roster of the Committee at the time of approval of this Standard. There are very detailed design rules for cranes and for the structures on which the rail is mounted. This special gantry crane is designed with a higher level of work duty and fast travelling speed and therefore plays a key role in facilitating the operations of yard stacking.

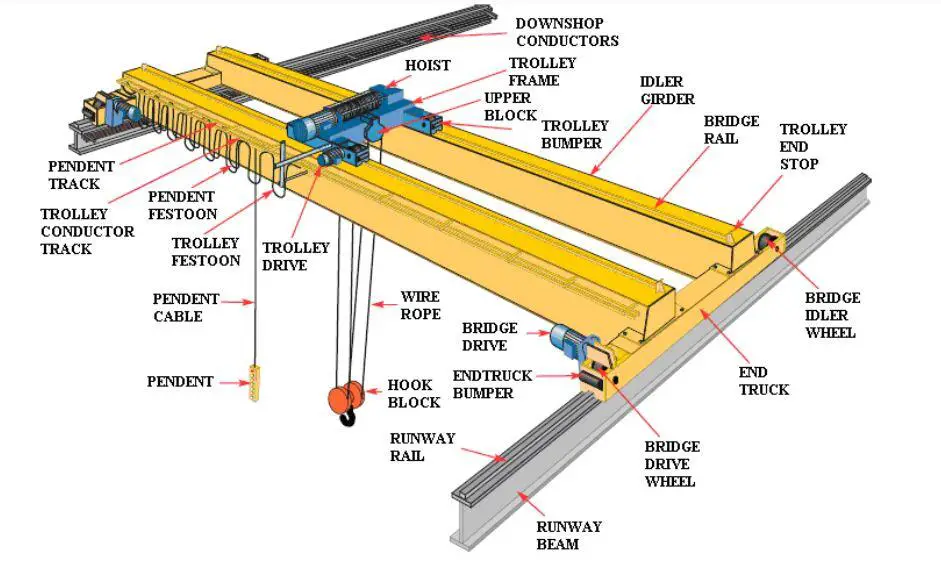

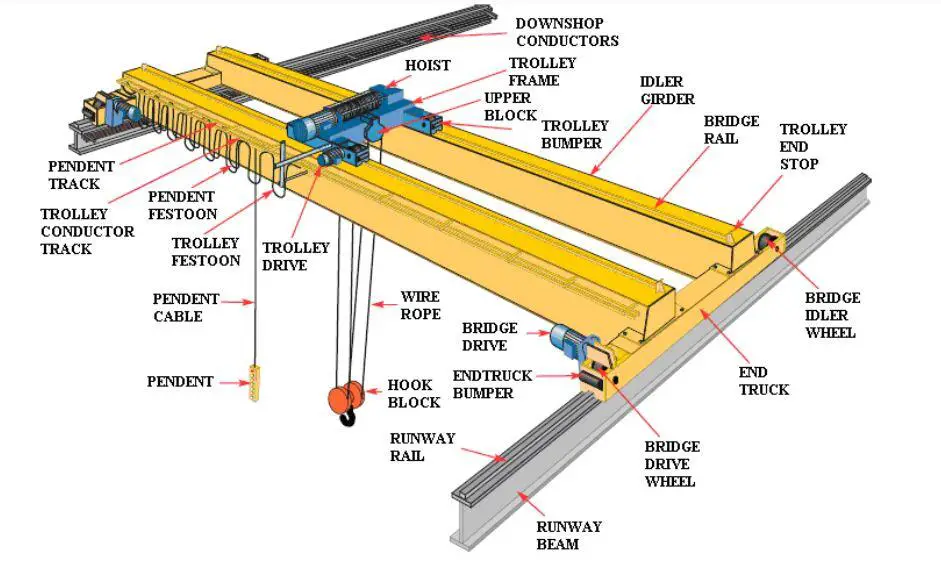

Small cranes may consist of an integrated double beam unit. With a wealth of experience Gantrail have developed specific checks that can be applied to designs which take. These beams are subjected to vertical and horizontal loads due to dead load of the crane the hook load and dynamic loads.

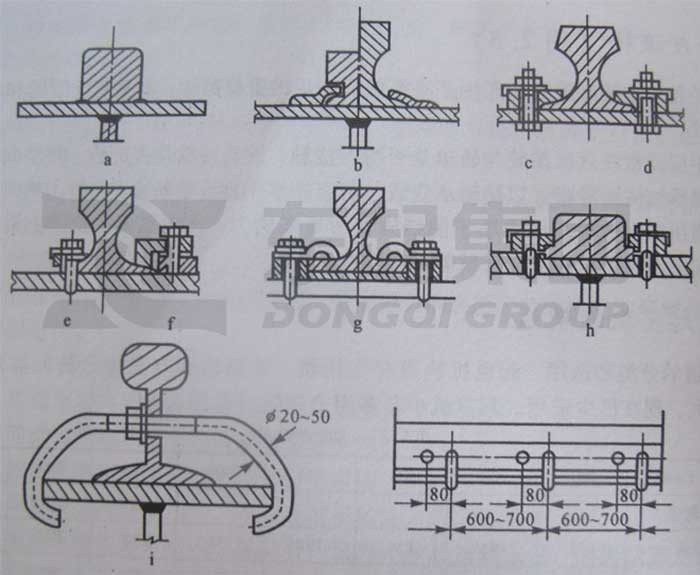

112 shows the types of beam sections used for gantry girder. 2 Foundations CHAPTER 7 GIRDER SUPPORT SYSTEMS 71 Continuous Girder Support. Effective installation of a crane rail system will have significant implications throughout the life of any project.

Rail mounted gantry cranes. Custom designed gantry cranes for sale. Concrete beam design for Gantry Cranes.

CHAPTER 6 COLUMNS AND FOUNDATIONS 6. Around 2500 for a non-adjusting height crane and would have an equivalent rating to the one being designed. How to design gantry crane.

Single girder gantry crane is a kind of lifting crane equipped with CDMD type electric hoist commonly used in workshop warehouse store yard railway. Priest Rapids 390T gantry crane for contractor. These date from the beginnings of the yard 1905-1916 and were significant innovations in the technology of their day.

Hungry Horse phase I 5 cranes for owner. Full gantry crane systems are the most popular configurationconsisting of two legs that ride on rail that is embedded flush with the top surface of the floor. The solid foundation for gantry crane is safety base of gantry crane operation.

Design of the railway entering directly into the sea-rail intermodal transport yard avoids the secondary transportation. Gantry crane girder design span and arm length design gantry crane wheel track crane span size and electric control etc. The design of a gantry crane girder therefore involves the selection of a suitable and workable steel model and section to satisfy the machine crane requirements loading equipment etc without leading to any structural or service failure.

16DZ2340400 16040501500 15590501700 14DZ2280200 and 14170501500 National Natural Science Foundation of. Basic A frame gantry hoist LK Goodwin 2012. Rail mounted gantry cranes RMGs are manufactured to individual customer needs in a variety of different stacking heights and spans.

Ground handle wireless remote control and cab. Especially with automated cranes the tolerances of the rail and the supporting foundations are critical to maximizing efficiency and reducing operational downtimes. The movement of the load is three-dimensionalThe crane is needed to lift heavy mass vertically and horizontally similarly the crane with load is needed to move along the length of the shedThe cranes are either hand-or-electrically operatedThe crane movement on the rails which are at its ends.

Gantry girder Design Loads The effect of cranes to be considered under the imposed loads should include the following. These hoists come with casters but the trolley and chain hoist must be purchased separately. This design allows motorized equipment like scissor lifts fork lifts carts and trucks to.

Bonneville Powerhouse intake gantry crane for contractor. We design supply and install a variety of crane rail fixing solutions to suit the type of crane and the underlying foundation either for piled foundation un-piled concrete slab or. Large cranes consist of a double truss unit.

Below is an example of a basic portable gantry hoist design. Normally for medium-duty say 25 to 30 t capacity cranes standard universal rolled I-beams are used. Avista Cabinet Gorge Dam gantry crane phase I for owner.

Vertical loads from the crane The eccentricity effects induced by the vertical loads and the impact factors Internal surge thrust across the crane rail and. Fort Randall bridge cranes rehabre-rate for contractor. Rail mounted gantry crane also known as RMG crane for short provides an efficient and safe way to stack large containers at ports and rail terminals.

In the following the 5Ton gantry crane. This calculation presents the basic structural design calculations of Gantry Crane structure supports is designed to carry the loading of the weight of equip. Am new to concrete designing this is the first time i will be involved in any of RC related design.

Of a crane gantry in a steel plant presents a startling contrast in that. Steel gantry cranes are the most common and most gantry crane plans are for steel cranes. The 5 factors affect gantry crane designs ie.

Building a gantry crane from steel is more expensive than wood but it can bear a much heavier load while still being relatively easy to build. Dognqi gantry crane - Custom gantry. The rails are equipped on a girder is called a gantry girder.

The RC Beam will in-turn support the Rails for the Gantry Crane 8 Ton and 10 Ton. July 13th 2017 - The track design of gantry cranes is key to the successful operation of the cranes whether they are manually operated RMGC or driverless ASC. Full Gantry Crane Systems.

They typically run in a straight line in a dedicated work area. Elements which make this yard unusual besides overall size and design are the six carfloat transfer bridges not included in this study and four snap-boom gantry cranes on the open pier. EWEB gantry crane modernization phase I II and III for owner.

Design Verification Technical Calculations There are very few design rules which full cover the installation of crane rails. No matter what condition it is there should be foundation under the gantry crane rail to make sure the ground can bearing the gantry cane and wheel Max. Supplied with Liebherrs 8 rope reeving anti-sway and drive systems the Liebherr rail mounted gantry crane delivers exceptional productivity and reliability.

Various components considers the design and detailing of the rail the girder the horizontal girder or surge plate and columns and founda. Types of custom gantry crane designs are for you to save time energy and money. Longitudinal horizontal thrust along the crane rail.

Crane Rail Classification And Selection Crane Rail Supplier

Crane Rail Refurbishment Maintenance Worldwide Gantry Rail

Rail Installation For Rail Crane Overhead Crane And Gantry Crane Dongqi Crane Rail Installation Tips

Design Of Gantry Crane Girders Bs 5950 Structville

Rail Installation For Rail Crane Overhead Crane And Gantry Crane Dongqi Crane Rail Installation Tips

Gantry Crane Rail Fastened To Concrete Foundation With Anchor Bolts Stock Photo Image Of Metal Connection 204155406

Crane Rail And Crane Rail Installation Tips Dongqi Hoist And Crane

0 comments

Post a Comment